Suspension grade PVC (SPVC) is produced in two independent plants in TCI Sanmar. Each plant has the design capacity of 200,000 tons per annum. Total capacity is 400,000 tons per annum.

SPVC is manufactured by polymerisation of Vinyl Chloride Monomer in closed reactors. PVC Slurry is dried in Fluidized Bed Dryers and packed as 25kg bags and 1250 kg jumbo bags.

PVC production process in both the plants are through Distributed Control System (DCS). TCI Sanmar site is fully integrated. Raw material, Utilities and Effluent treatment facilities are all available at the door steps of PVC production units.

PVC Grades

PVC – K7001

PVK-7001 is a medium molecular weight Polyvinyl Chloride homopolymer suspension resin produced by suspension process C K-7001

Applications:

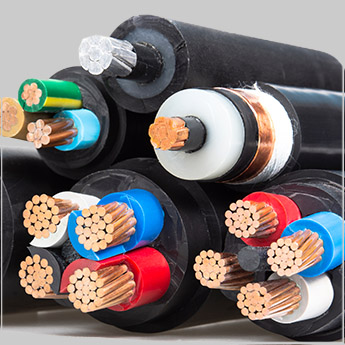

- Wire and cable insulations and sheathing

- Rigid Extrusion Compounds

- Footwear Compounds

Packaging:

- 1 MT Jumbo woven sacks bag with inner liners

PVC K6701+

K-6701 is a medium molecular weight Polyvinyl Chloride homopolymer suspension resin produced by suspension process

Applications:

- Rigid Pipes-Portable water pipes, SWR Pipes, Drainage Pipes

- Rigid duct, Conduit & Trunking for telecommunication & Cable

Packaging:

- 1.25 MT Jumbo woven sacks bag with inner liners

PVC – K 5701

K-5701 is a low molecular weight Polyvinyl Chloride homopolymer suspension resin produced by suspension process

Applications:

- Fittings for PVC Pipe

- Rigid Injection Moulded Products

- Calendering Sheet & Film

Packaging:

- 1 MT Jumbo woven sacks bag with inner liners